Taiwan: Supporting Indonesia Smart Manufacturing Future

2023.12.06 (Wed.) - 2023.12.09 (Sat.)

Hall A3, Stand No. 3216

Taiwan leads the way in manufacturing innovation, known for unrivaled quality, efficiency, and reliability. Prepare to be captivated by 50 esteemed Taiwanese exhibitors at Manufacturing Indonesia 2023, presenting cutting-edge robotics, automation, machinery, and precision tools. Visit Taiwan Smart Manufacturing Pavilion at A3, 3216 to explore the latest trends and innovative solutions. Don't miss the press conference on Dec. 6th, when six Taiwanese companies will demonstrate their latest innovation on smart and green manufacturing solutions from the perspectives of machine tools, components, accessories, AI and machine learning and etc. Discover how these technologies drive efficiency, productivity, and sustainability in your manufacturing operations!

- Taiwan Smart Manufacturing 360 Stand

10.00 – 18.00 / 6 Dec. – 8 Dec. (Wed – Fri); 10.00 – 17.00 / 9 Dec. (Sat)

_%E6%B4%BB%E5%8B%95%E8%A1%A8_%E4%BF%AE%E6%94%B92.jpg?width=2000&height=1056&name=2023%E5%8D%B0%E5%B0%BC%E8%A3%BD%E9%80%A0%E5%B1%95_DM-40x40cm_1031-1%20(002)_%E6%B4%BB%E5%8B%95%E8%A1%A8_%E4%BF%AE%E6%94%B92.jpg)

Press Conference & On-site Events

Taiwan: Supporting Indonesia Smart Manufacturing Future

-

10:30 - 11:00

Reception

-

11:00 - 11:10

Opening

-

-

11:10 - 11:16

Next-Generation 50% Energy-Efficient Air Compressor

presented by Han Lin, CEO of ELITE AIR Compressor

Next-Generation 50% Energy-Efficient Air Compressor

ELITE AIR compressor will unveil their upcoming next-generation energy-efficient air compressor model, the "Air Levitation Air Compressor," at this exhibition. This compressor breaks away from the conventional operation mode of traditional air compressors by introducing the latest head design, making the entire machine more energy-efficient, more efficient in operation, and less prone to damage.

1. Energy Efficiency - 50% more energy-efficient than the previous generation screw-type air compressors, with a return on investment within one year.

2. Almost Maintenance-Free - Unlike screw-type air compressors that require frequent maintenance, the maintenance cost over 5 years equals the cost of buying a new machine.

3. Oil-Free - Produces cleaner compressed air, resulting in better product quality across various industries.

4. Environmentally Friendly - Eliminates the need for waste oil disposal.

presented by Han Lin, CEO of ELITE AIR Compressor

presented by Han Lin, CEO of ELITE AIR Compressor

-

11:16 - 11:22

HIWIN Smart Manufacturing Solutions

Mr. Zack Chen, Sales Representative of HIWIN

HIWIN Smart Manufacturing Solutions

HIWIN i4.0BS® is the first intelligent 4.0 ball screw in the world. It combines a multifunction sensor to detect vibration and temperature with professional algorithm. Users can monitor the status of each machine in real time from the APP to arrange maintenance schedule. It can avoid machines’ unexpected shutdown, and achieve high machine utilization, energy saving and environmental protection. HIWIN wielding robot system include 10kg HIWIN Articulated robot RA610 and wielding power source for TIG and can combine with linear axis, head stock, tail stock, index table and positioner options.

Mr. Zack Chen, Sales Representative of HIWIN

Mr. Zack Chen, Sales Representative of HIWIN

-

11:22 - 11:28

CHMER’s Intelligent Wire Cut EDM

presented by Sephiroth Chao, Regional Sales Manager of CHMER

CHMER’s Intelligent Wire Cut EDM

presented by Sephiroth Chao, Regional Sales Manager of CHMER

presented by Sephiroth Chao, Regional Sales Manager of CHMER

-

11:28 - 11:34

Corner Overtaking in the AI Era: How Taiwan’s World Class Manufacturers Accelerate AI Adoption to Create AI-Powered Smart Products and Digital Factory

presented by Jonathan Yu, Global General Sales Manager, PROFET AI

Corner overtaking in the AI Era : How Taiwan’s world class manufacturers accelerate AI adoption to create a AI-powered smart product and digital factory

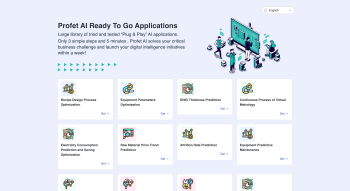

PROFET AI's No-Code AutoML Platform serves as a virtual data scientist for industries, allowing experts to swiftly build and deploy high-quality prediction models, addressing production and digitalization challenges. Trusted by global leaders in EMS, Semi-OSAT, PCB, IC design, and more, Profet AI implements AI solutions within a week using successful cases from industry giants. The company has doubled its business scale and boasts an exceptional capital utilization efficiency, attracting over 100 medium- to large-scale manufacturing clients across 14 sectors. Notably, more than 70% of these clients are industry leaders and publicly listed companies, such as AUO, Qisda, Everest Textile, WUS Printed Circuit, Eternal Materials, and MAXXIS. Learn more at http://www.profetai.com/

presented by Jonathan Yu, Global General Sales Manager, PROFET AI

presented by Jonathan Yu, Global General Sales Manager, PROFET AI

-

11:34 - 11:40

Techman AI Cobot

presented by William Djohar, General Manager of PT. Ganesha Otomasi Teknik (Techman Robot’s agent)

Techman AI Cobot

TECHMAN ROBOT is an industry-leading AI robotics design and manufacturing company dedicated to improving businesses through (robotic) technology applications. The company specializes in collaborative robot (Cobot) and smart vision technologies.

TM AI Cobot S Series, what sets our cobots apart from the industry-standard robotic arms is our “AI Vision” technology. Our collaborative robots increases production throughput as they can sense their environment and people they operate with. By giving cobots “eyes” to see, it creates a world of difference in how they can perform. AI Cobots can boost quality, improve flexibility, and future-proof your production.

presented by William Djohar, General Manager of PT. Ganesha Otomasi Teknik (Techman Robot’s agent)

presented by William Djohar, General Manager of PT. Ganesha Otomasi Teknik (Techman Robot’s agent)

-

11:40 - 11:46

The Key to Automaton -Mindman’s Smart Pneumatic Components Solutions

presented by Nick Lee, Sales Representative, MINDMAN

The Key to Automaton -Mindman’s Smart Pneumatic Components Solutions

•Applications for robot arm

One R-plate can match multiple T-plates.

T-plates can be installed with gripper,

pneumatic tool or vaccum pad.

Great production flexibility, save wiring

time and lower labor cost.

• Self-locking mechanism

Prevent the T-plate dismount from R-plate

when the pneumatic source is accidently removed by spring force.

• ISO adapter board

ISO specification adapter board for good

interchangeability for most of the robot

presented by Nick Lee, Sales Representative, MINDMAN

presented by Nick Lee, Sales Representative, MINDMAN

-

-

11:50 - 12:00

Q & A

Fluid Power Components

-

14:50 - 15:00

Reception

-

-

15:00 - 15:10

Smart Tech., Forging A New Future Connection

presented by Mr. Nick Lee, Sales Representative of MINDMAN

-

15:10 - 15:20

Eco-Friendly and Energy-Saving: Highly Corrosion-Resistant Hard Chrome Plated Steel Bar

presented by Ms. Evelyn Lo, Deputy Manager of FU-LONG

-

15:20 - 15:30

C-JAC Shock Absorber: Your Smart, Efficient, and Energy-Saving Manufacturing Companion

presented by Ms. Josephine Lin, Marketing Director of C-JAC

-

-

15:30 -

Q & A

Taiwan Smart Manufacturing X First Machinery

Taiwan Smart Manufacturing X OTT

Taiwan Smart Manufacturing X OBI

Taiwan Smart Manufacturing X ASP

Don't miss out on these informative and engaging events!

Sign up now

Partner Company

.png?width=7086&height=911&name=LOGO%20ASP%20(dari%20P_Alex).png)